Protecting workers from heat stress is more critical than ever. As I write this, southeastern Canada and the northeastern United States, are experiencing an extreme heat warning. This has become increasingly common in recent years, not just here, but globally. 2023 brought record-breaking temperatures, widespread wildfires, and severe climate challenges across the world. These high temperatures not only pose serious health risks but also jeopardize productivity and safety in work settings.

For years, organizations have relied on traditional methods such as hydration, rest breaks, and ventilation to mitigate heat stress. While these measures have been somewhat effective, they are no longer sufficient in the face of escalating climate challenges.

Organizations now need software solutions that empower them to proactively prepare for and respond to the rising frequency of extreme and potentially fatal, heat events. This blog aims to offer guidance on how to leverage technology to enhance organizational readiness and resilience in the face of climbing temperatures.

Record-breaking Heat in 2023

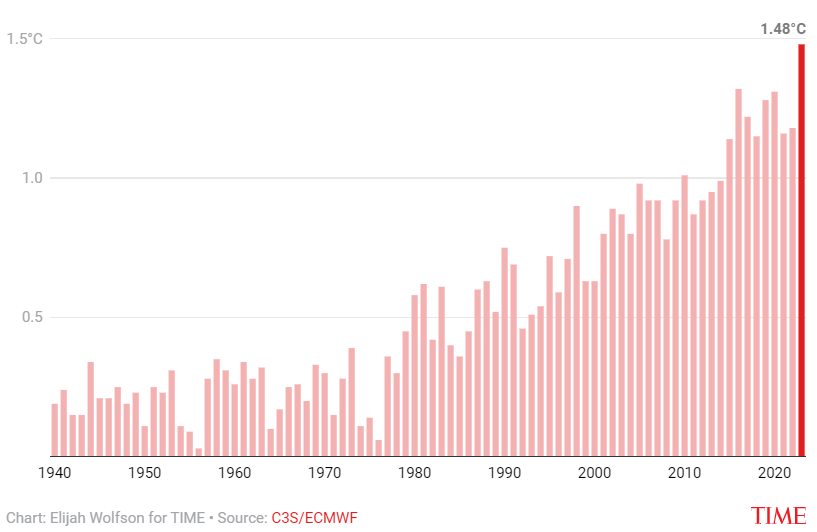

According to leading weather monitoring organizations like the European Union’s Copernicus Climate Change Service (CCCS), 2023 shattered the previous heat record set in 2016, surpassing it by a significant margin1. This unprecedented average temperature was linked to deadly heat waves, coastal flooding from rising ocean levels, and wildfires globally, causing an estimated $28 billion in damages in the U.S. alone1.

Source: https://time.com/6554830/2023-hottest-year-ever/

The extreme heat of 2023 was not an anomaly but part of a long-term trend. NASA reports that the last decade has been the warmest on record3. Forecasters predict another year of extreme heat in 2024, with data suggesting that baseline temperatures will only continue to rise3.

Organizational Impacts, Risks, and Safety Standards for Workers

The proportion of people exposed to extreme work-related heat has risen significantly, from 65.5% in 2000 to 70.9% today3. Labor force trends indicate that by 2030, 2.2% of total working hours worldwide will be lost to high temperatures, equivalent to the productivity of 80 million full-time jobs4. Extreme heat is also linked to increased mental health issues, such as depression, while exacerbating respiratory and cardiovascular diseases5. Considering these statistics, there is a pressing need for organizations to adopt processes and technology to help them identify, assess and mitigate the risk of heat stress on their workforces.

As regulators worldwide discuss new standards for managing workplace heat stress, the responsibility currently falls on employers to implement practical measures to mitigate exposure to extreme heat. In early 2024, the American Society of Safety Professionals (ASSP) announced the first national voluntary consensus standard addressing heat stress for workers in construction and demolition6. Released in February, this standard provides guidance on protecting workers from heat stress, acclimating them to high temperatures, and training employees and supervisors6. It includes checklists and flowcharts to help companies develop effective heat stress management programs, bridging the regulatory gap6. Leveraging this voluntary standard alongside software can help organizations scale heat stress protection programs, delivering significant benefits.

Challenges with Monitoring and Managing Heat Stress in the Workplace

Monitoring and managing heat stress in the workplace is a complex task that presents several challenges for organizations, especially in fields such as construction and demolition where workers are regularly exposed to extreme temperatures. An organization must take several steps to manage heat stress effectively, yet various obstacles can complicate these efforts.

- Accurate measurement of weather: Organizations need to accurately measure heat and humidity levels to assess the risk of heat stress. The collected data must then be compared against humidex charts or other heat stress indices to determine the degree of risk and the necessity for controls, such as scheduling breaks. This process can be subjective and prone to inaccuracies without precise instruments and the required expertise.

- Interpreting Wet Bulb Globe Temperature (WBGT) readings: Measuring temperatures with devices such as WBGT meters to gauge heat-related stress on employees in direct sunlight can be complex. Once a heat stress reading is obtained, it needs to be manually documented and compared to established standards like the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs). This involves consulting booklets or policy documents and accurately interpreting the results, a process that is susceptible to human error.

- Managing employees shift schedules: Accounting for workers on different shifts or varying shift lengths adds complexity to heat stress management. Different times of day and durations of exposure can significantly impact heat stress risk, necessitating tailored approaches for each group of workers. This creates an overwhelming administrative burden for Industrial Hygienists, especially those already balancing multiple responsibilities.

Without standardized procedures and software tools, organizations may struggle to consistently and effectively apply heat stress controls. This can lead to suspicions from workers and unions that management is manipulating data or rules to avoid implementing necessary safety measures, fostering distrust and potentially generating conflicts.

The Power of a Calculation Engine for Heat Stress Monitoring

Industrial hygiene (IH) software empowers organizations to streamline and standardize the collection, monitoring, analysis, and management of IH exposures. However, for organizations with employees working in weather-sensitive environments, particularly those using a WBGT meter to gauge heat-related stress, it’s essential to account for a variety of atmospheric factors. These include temperature, humidity, wind speed, sun angle, and cloud cover. Standard industrial hygiene functionality may not meet these complex needs. In such cases, organizations require a best-in-class IH solution with a flexible and powerful calculation engine capable of handling the intricacies of heat stress exposure calculations.

Here’s how leveraging IH software with an advanced calculation engine can simplify heat stress management:

-

Simplified heat stress evaluation:

Automated calculations that measure heat and humidity levels assess worker exposures to heat against permissible limits, saving time and minimizing data errors. This automation also simplifies the collection of employee data across different shifts or varying shift lengths through a time-card feature, accurately estimating heat exposure across large, dispersed workforces where sunlight exposure may vary, facilitating quicker identification of when controls need to be implemented.

-

Improved accuracy in heat stress management:

An advanced calculation engine allows industrial hygienists to establish an equation library of layered calculations available to assess employee’s heat exposures accurately and efficiently. Integrating monitoring data with preset equations enables heat exposure assessment and compliance evaluation, minimizing the risk of errors associated with manual calculations. Given the complexity of WBGT monitoring calculations, automated tools are essential to ensure accurate compliance evaluations, as data entry errors could lead to severe consequences for worker health and safety.

-

Enhanced risk awareness:

With numerous employees working across various locations, determining which individuals are at highest risk from heat exposure can be challenging and time-consuming. Automating these calculations, then visualizing their outputs on configurable reports or dashboards can help provides real-time insights to identify at-risk areas and enable prioritized intervention.

-

Integration of IH Calculation Engine Data with Occupational Health (OH) Workflows:

An integrated IH and OH solution enables organizations to seamlessly enroll employees into surveillance exposure groups (SEGs) using IH calculation engine monitoring results. This initiates an OH workflow that ensures workers facing heat stress risks receive timely attention and interventions, prioritizing them for supervisor check-ins or proactive health clinic visits. This integration enhances worker safety and effectively mitigates health risks associated with heat exposure.

Standard IH solutions frequently lack the ability for handling organizations with employees working in weather-sensitive environments, advanced IH solutions equipped with robust calculation engines help automate heat stress assessments, minimizing errors, and integrate real-time monitoring data for precise compliance checks.

Prepare for the future

The record-breaking heatwaves of recent years underscore the critical need for effective strategies to manage workplace heat risks. Traditional approaches like hydration and rest breaks are no longer sufficient in the face of escalating climate conditions. The integration of advanced industrial hygiene software, equipped with powerful calculation engines and monitoring capabilities, is essential. By embracing these technologies and adhering to emerging standards, organizations can effectively mitigate health hazards, boost productivity, and safeguard worker well-being in an increasingly warming world.

Sources:

1 https://time.com/6554830/2023-hottest-year-ever/

3 https://www.weforum.org/agenda/2024/05/climate-change-health-global-workforce/

4 International Labour Organization. (2019). Working on a warmer planet: The impact of heat stress on labour productivity and decent work. Publications Production Unit.

5 https://www.weforum.org/agenda/2023/10/how-we-can-adapt-our-workplaces-for-extreme-heat/

6 https://www.assp.org/news-and-articles/assp-publishes-first-standard-on-heat-stress-in-construction