In a recent webinar titled “How to Error Proof your Permit to Work Program”, Cority explored the common challenges faced by organizations managing Permit to Work (PTW) programs, and how EHS professionals around the world are adopting software to increase the reliability and effectiveness of the PTW processes.

In this blog, we’ll recap some of the key insights shared on the topic, and address some audience questions that we weren’t able to cover during the webinar. Read on to learn more about how your organization can leverage the power of technology to error-proof permit to work programs.

Learning From Past Mistakes

The Piper Alpha Disaster

The Piper Alpha Disaster is a textbook example of the real consequences of a permit to work system failure. On the night of July 8, 1988, a poorly-controlled permit to work task resulted in the uncontrolled venting of liquid natural gas vapor on the Piper Alpha offshore oil platform operating off the coast of Scotland. The flammable vapor quickly ignited, resulting in a massive explosion and fire that destroyed the rig and took the lives of 169 workers aboard.

While we’ve learned much in the nearly four decades since this terrible event, the truth is that permit to work system failures continue to this day. According to the U.S. Bureau of Labor Statistics, “confined space entry incident” claim about 130 workers each year. Falls from height claim another 700 people annually. But why?

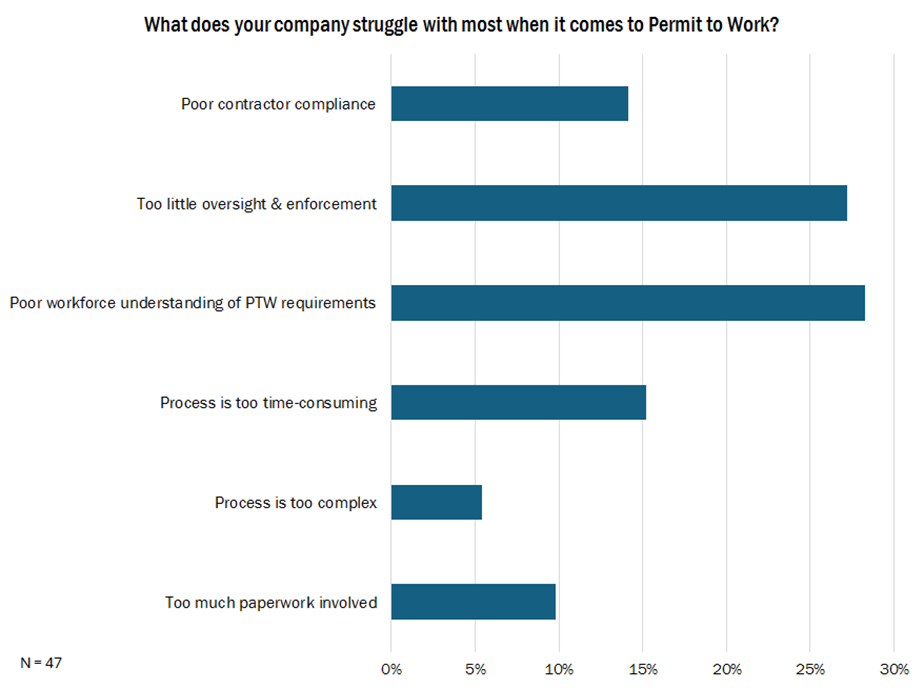

Sadly, PTW failures are often attributed to known errors in the way these programs are designed, maintained, and executed. During our recent webinar, we asked participants what they saw as their organization’s most significant challenges to realize effective and sustainable PTW management. Here’s what they said:

So, how can we begin to address these common errors and mitigate the underlying operational weaknesses in our PTW programs before they result in catastrophic losses? In the webinar, we offered a few ideas.

Error #1: PTW programs are too complex for the individuals that are required to follow them.

The more complexity we add to our PTW programs, the more likely we will see individuals circumventing PTW requirements. Thus, it’s important to design PTW processes to encourage discussion and engage workers by keeping language simple, keeping requirements clear and straight-forward, and reducing paperwork burdens whenever possible.

How software helps: Digital PTW solutions offer organizations the ability to consolidate PTW forms to reduce administrative effort, configure user interfaces to ensure simple navigation, and tailor workflows to guide the user along the desired PTW process pathway.

Error #2: PTW programs don’t align with operational realities.

One of the biggest challenges that companies encounter is that their PTW programs are too rigid to reflect operational realities. Creating PTW workflows that introduce bottlenecks and delays only encourage workers to look for workarounds that can lead to disaster. Aligning your PTW requirements to what the company can reasonably manage is critical for operational sustainability.

How software helps: Digital PTW solutions help short-circuit process bottlenecks by allowing workers to request permits–and for permit issuers to approve them-right from their mobile device, anywhere, anytime, while also enabling periodic work-in-progress checks to ensure required controls are actually implemented.

Error #3: Permit issuers cannot validate worker competency.

As permit issuers often lack real-time access to worker training data, they often make uninformed judgments on worker competency when assigning PTW tasks, increasing the risk of failure. Creating processes that improve front-line access to training data to inform decision-making is key.

How software helps: By integrating training and certification data into their digital PTW process, organizations can enable permit issuers to make more informed decisions on PTW task assignments and avoid sending untrained and unqualified workers into high-risk situations that can increase the risk of something bad happening.

Error #4: EHS leaders lack overall PTW program visibility

It’s extremely difficult for EHS leaders to identify and address gaps in their PTW performance if they lack reliable access to real-time data. Many firms lack the ability to monitor program metrics in real-time to easily collect and analyze PTW data and guide time-oriented decisions. They also have difficulty sharing PTW learnings across teams to facilitate firm-wide improvement.

How software helps: Digital PTW applications offer huge benefits in better visualizing information to ensure more data-driven decisions, enable earlier interventions to reduce risk, and support prioritization of critical actions all while lowering administrative burdens.

To learn more, check out our ebook, Preventing SIFs with Digitization: Reduce Serious Injuries and Fatalities with Technology

Making the Transition to Permit to Work Software

Digitizing your Permit to Work program via software can introduce some additional questions regarding PTW process design, performance monitoring, and compliance that should be carefully considered. Below, we offer some insights on things to consider when evaluating a shift to a digital PTW program.

Q: Some organizations require permits to work for any task that does not have a written procedure. This approach often leads to a significant increase in permit volumes, and can result in task overload for permit issuers. Is there a better guideline to determine when permits should be used?

While regulations often outline specific actions that must be taken in a given circumstance, businesses can elect to implement EHS policies that impose greater requirements than the minimum dictated by law. In fact, that approach is widely encouraged.

But if used improperly, organizational policies can actually undermine the very behaviors that the business seeks to promote. When determining how to apply your permit to work rules, some thoughtful planning is required. Here are a few ideas to keep in mind:

- Consider context – We need to remember that permit to work was designed to create a system of reasonable checks to ensure that potential exposures that could result in serious, life-threatening or life-altering impacts were adequately controlled before and during the activity. In that sense, using a permit to work to manage a low-risk activity (e.g., housekeeping task) is a bit like using a sledgehammer to open a walnut. We should instead ask ourselves whether there is a more appropriate tool that could be used to help workers identify, assess, and manage hazards related to these lower-risk tasks. This will keep PTW focused on the high-risk tasks where they are needed most, and prevent creating more permits than can be reasonably managed.

- Consider operational constraints – Remember that a PTW process requires the review, approval, and continual oversight of permitted activities. Review your existing resources and ask yourself whether you can realistically manage permits covering a wide scope. Remember – any policy your business implements becomes enforceable by law. So, ask yourself whether you have the capacity to ensure stringent adherence to PTW requirements for activities that really don’t need it.

- Consider overall effect on compliance – While we want every worker to follow every rule every time, the truth is that workers are constantly assessing risk in a given context and making quick judgments on where a policy or rule must be strictly followed, and where they can be bent slightly to enable work to get done. This is how the natural variability of risk is managed in real-time.

For that reason, we want workers to know-without a doubt-that if PTW requirements are not strictly adhered to at all times, the potential for catastrophic failure increases significantly. There is no margin for error, and no wiggle room around the rules. Yet, if we impose PTW requirements on tasks that arguably don’t need them, we risk creating an environment where workers feel justified bending specific PTW rules that they believe aren’t warranted in that situation. Unfortunately, that can create behavior patterns where workers begin to question all PTW requirements, even when they are absolutely needed.

In the end, those who perform and supervise PTW tasks need to know that the requirements they are asked to follow make sense in the context of what they are doing. If we impose rules that are overly restrictive, difficult or time-consuming to complete (especially for simple, routine or low-risk activities), we risk undermining the very system when we need it to work flawlessly.

Q: Is a permit to work required for work on energized systems or components if you have a robust lockout-tagout (LOTO) process?

Most health & safety authorities have imposed regulations that require power sources for equipment, machinery or devices to be de-energized and locked out before the performance of any related maintenance, repair, or service. But what happens when the system cannot be fully de-energized and isolated? In these cases, organizations may turn to industry standards for guidance on how to manage the residual energy in that system, or create policies that dictate how the work can continue.

In the latter case, businesses may choose to require workers to request a permit to work for that activity. The permit to work is designed to ensure that all measures required to control related energy sources, and the risk of re-energization, during the task are implemented. But if there’s no residual energy in the system after system lockout, there’s really no need to issue a permit, unless the tasks involved other aspects that require PTW management.

Q: Can employees and/or contractors be required to undergo regular medical evaluations before they are authorized to perform permit to work tasks?

There are many organizations globally that impose medical requirements that workers must meet before they are allowed to perform high-risk, permit-required, tasks. Generally, these evaluations are designed to identify those individuals whose medical status could make them more susceptible to injury in a permit-required task. We wouldn’t want to send a worker with claustrophobia into a confined space, nor assign an individual with vertigo to work at height.

Such decisions, however, are rife with other considerations, including local legal context, worker rights, and health privacy concerns to name a few. For these reasons, organizations should speak with their EHS professionals and legal counsel before imposing any medical evaluation requirement in their workplace.

For firms assessing whether to include medical evaluations within their PTW program, it’s important that they consider how such health data will be effectively integrated in their process to inform front-line PTW decision making. Many digital platforms, like Cority’s Safety Cloud, offer capabilities to capture medical evaluation results within highly-secure electronic medical records. The organization can then query all EMRs, and using specific criteria, auto-enroll individuals with medical clearance for specific PTW tasks into designated groups (rosters). In that respect, permit issuers would be able to make inform decisions on PTW task assignment by reviewing, in real-time, the current roster of employees approved for that task, right from their mobile device, wherever they are. It’s just another example of the data available when aggregating health & safety insights into a single, unified, cloud-based software application.

Q: Many jurisdictions dictate that a physical copy of the permit is posted at the work area. How do electronic Permit to Work solutions enable compliance to these requirements?

Fortunately, most digital permit to work software applications offer the ability for users to print out a physical copy of the permit and post it at the workplace. That said, printing the permit at the start of the task doesn’t immediately address all potential issues. In the event that information must be recorded on the permit periodically (e.g., results of atmospheric testing during a confined space entry), workers might find the digital and printed permit copies out-of-sync. Obviously, printing out an updated permit is possible, but perhaps not always practical.

Fortunately, with the rapid adoption of digital technologies across industry, regulators are slowing becoming more receptive to the idea of digital permits to work, albeit with a few key caveats:

- Accessibility: Specific regulations required that permits to work must be made readily available at the work area so that workers involved in the task, or bystanders who may be impacted by the PTW activity, can review the permit and confirm that necessary control measures are implemented (see 29 CFR 1926.1205[c]). In that respect, when using a digital PTW solution, the employer must ensure that all workers have reliable access to the digital permit, often through a kiosk or mobile app. Most importantly, employers must be able to demonstrate that the workers were trained in how to access the permit, when required. This can be particularly challenging when contractors are involved in PTW tasks.

- Auditability: One of the chief reasons for documenting permits to work is to create an objective paper trail that can be used retrospectively to assess conformance to PTW procedures. When adopting a digital PTW solution, ensure that the software offers robust audit logs to support auditability and traceability, enabling you to prove all applicable measures to control exposure to PTW risks were implemented correctly.

- Signatures: Some regulations dictate that the permit must capture the signatures of all employees engaged in the PTW task, and/or the permit issuer. If required, it’s critical that the digital PTW application selected includes capabilities to capture electronic signatures, and that those signatures can be exported to printed permit copies, when needed.

Final Thoughts

Effective EHS management requires that we continuously learn from our past mistakes and use these insights to guide how we can build programs that are more adaptive to our given context and more effective at managing risk.

As organizations globally seek to reduce the risks of serious injuries and fatalities (SIF) across their operational footprints, they must begin to explore how to optimize processes critical to managing high-risk work, including Permit to Work programs. Digital transformation of these programs via software is showing huge promise, and hopefully opening the door to new ways to manage operational risk more effectively, and to enable better decisions when and where they are needed most.